MiniTest 3100

The MiniTest 3100 is no longer available and has been replaced by successor model MiniTest 4500/2500.

The all-rounder: the MiniTest 3100 can be combined with a variety of probes to make it suitable for use in many different areas. Measurement is non-destructive and covers the following ranges:

- 0 – 50mm for non-magnetic coatings on steel

- 0 – 100mm for insulating coatings on non-ferrous metals

- 10 – 200µm for copper coatings on insulating base materials

- 0 – 1600µm for powder coatings on steel and non-ferrous metals

We are happy to assist

finding the best measuring solution for your specific application as well as with all questions concerning coating thickness measurement in general and also non-standard measuring tasks, calibration, quality requirements and much more. It is a pleasure for us to share our experience of more than 75 years with you.

Beatrix Badura-Yilmaz

Commercial director

Tel.: +49 221 75204-32

beatrix.badura-yilmaz@elektrophysik.com

Product infomation

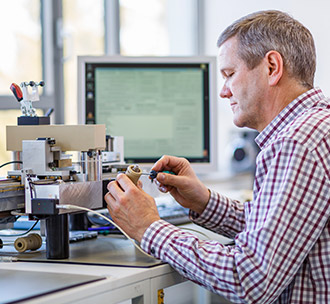

Flexible application using the MiniTest 3100

The MiniTest 3100 system has numerous probes suited to a variety of coating thickness measurement tasks, as well as different calibration methods and analysis options:

- Specialised probes can be supplied,g. completely sealed probes for use in wet areas, and heat-resistant probes for temperatures up to 250°C and 350°C

- A special calibration method allows for countless different applications; calibration using unidentified coatings (CTC method) enables calibration on objects with inaccessible uncoated areas.

- The calibration curve recorded in the factory is stored in the probe connector making it easy to interchange probes on site.

- All probes are equipped with durable poles to ensure long life even for frequent use on abrasive substrates. The pole surfaces are highly polished.

Application

Non-destructive coating thickness gauge for:

- Non-magnetic coatings on steel

- Insulating coatings on non-ferrous metals

- Copper layers on insulating substrates

- Powder coatings on steel and non-ferrous metals

Measuring principles

- Magnetic induction (F-type sensors) according to DIN EN ESO 2808, method 7C

- Eddy current (CN- and N-type sensors) according to DIN EN ESO 2808, method 7D

Features

- Wide range of wear resistant probes adaptable for varied applications

- Universal probes with automatic substrate detection allows quick measurement on steel and non-ferrous metals

- Wear resistant special probes with a virtually unlimited life

- High accuracy in measurement and repeatability

- Storage and evaluation of measuring values

- Special calibration function for rough surfaces and calibration through unknown coating (CTC method)

Supply schedule

- Coating thickness gauge MiniTest 3100

- 1 x 9 V battery 6 LR 61

- 1 cross tip screwdriver

- Operating instructions on CD

- Short operating instructions

- Factory certificate

- Plastic carrying case