MiniTest 7400

A high-end device for coating thickness measurement from ElektroPhysik. The MiniTest 7400 can take a diverse range of measurements and always gives you readings of the highest precision. The following features combine to make the MiniTest 7400 an unbeatable tool:

- Wide range of external, interchangeable sensors for use in every situation

- Graphic display with simplified user guide to instantly show statistical values, trend diagrams and histograms

- Technologically advanced and unique in terms of precision and reproducibility thanks to SIDSP sensors

We are happy to assist

finding the best measuring solution for your specific application as well as with all questions concerning coating thickness measurement in general and also non-standard measuring tasks, calibration, quality requirements and much more. It is a pleasure for us to share our experience of more than 75 years with you.

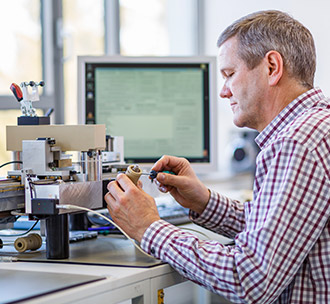

Frank Osthoff

Head of international sales & service

Tel.: +49 221 75204-31

frank.osthoff@elektrophysik.com

Product infomation

State of the art for coating thickness measurement

The coating thickness gauge MiniTest 7400 is an indispensable tool for measuring non-magnetic coatings (paint, synthetic material, chrome, etc.) on ferromagnetic substrates (steel), or insulating coatings (lacquer, enamel, synthetic material, etc.) on conductive substrates (aluminium, copper, stainless steel, etc.).

The MiniTest 7400 enables a wide range of measurements, from the thinnest coatings in the sub-micrometre range (e.g. galvanised coatings), to thick coatings (e.g. flame retardant coatings in steel constructions, rubber coatings, etc.). Measuring objects with difficult geometries (e.g. the measurement of steel pins, or in recesses and holes, etc.) are also no problem for the MiniTest 7400.

SIDSP sensors feature high levels of accuracy and are also extremely durable, easily withstanding years of use even on rough surfaces. Each sensor…

- is subject to fully automated testing under workshop conditions,

- is equipped with 50 calibration points to correct even the smallest deviation,

- undergoes a climate cycle during production enabling it to automatically compensate for the influence of temperatures.

Ease of use is a further feature: The coating thickness gauge MiniTest 7400 is controlled via a graphic display and provides common PC functions: context-specific help, saving of readings in a folder structure, navigating via menus displaying symbols and text. The user guide is currently available in 6 languages (German/English/French/Spanish/Italian/Portuguese).

Application

Non-destructive coating thickness measurement:

- Non-magnetic coatings like varnishes, enamels, chrome and zinc on ferromagnetic base materials (e.g. steel)

- Insulating coatings like varnishes and anodising aluminium on non-ferrous metals (e.g. aluminium, copper, die-cast zinc)

Measuring principles

- Magnetic induction (F-type sensors) according to DIN EN ESO 2808, method 7C

- Eddy current (N-type sensors) according to DIN EN ESO 2808, method 7D

Features

- Precision in coating thickness measurement of up to 100 mm / 4 inches

- Increased accuracy and reproducibility by sensor-integrated digital signal processing (SIDSP®)

- Universal probes with automatic substrate detection for quick measurements on steel and nonferrous metals

- Wear resistant probes with practically unlimited service life

- Optimal temperature compensation

- High precision characteristic curves with up to 50 data points in the factory calibration

- User guidance in 4 languages, others under preparation

- Infrared data transmission (IrDA) to PC and printer

Supply schedule

- MiniTest 7400 device

- Software MSoft 7 Professional

- User guidance German/English/French/Spanish

- Quick reference guide

- 4 AA cells, type LR06

- Plastic carrying case