MiniTest 725-735-745

Devices in the MiniTest 700 series are our best sellers – and for good reason: they have diverse applications and deliver precise readings, all at unbeatable value for money.

Overview of benefits:

- Digital processing of readings by the sensor for quick results

- Durable sensors for a long service life

- Diverse range of applications for measuring coating thickness up to 35mm

- Graphic menus and guide texts in 20 languages – ideal for use in a multi-national team

We are happy to assist

finding the best measuring solution for your specific application as well as with all questions concerning coating thickness measurement in general and also non-standard measuring tasks, calibration, quality requirements and much more. It is a pleasure for us to share our experience of more than 75 years with you.

Katja Lux

International Sales

Tel.: +49 221 75204-33

katja.lux@elektrophysik.com

Product infomation

Precision measuring instrument in 3 variants according to requirements

The coating thickness gauge MiniTest 700 is available in 3 different models:

MiniTest 725: The basic version with integrated sensor, a compact design and inexpensive.

MiniTest 735: The standard version with the external sensor connected to the device by a cable to make measurement easy.

MiniTest 745: The flexible version with interchangeable sensors that can be connected to the device either by cable or wirelessly via Bluetooth for greater freedom when measuring coating thickness.

All three versions in the MiniTest 700 series enable the non-destructive measurement of coating thickness for non-magnetic coatings (paint, synthetic material, chrome and other electro-plated, non-magnetic coatings, etc.) on ferromagnetic substrates (steel/iron), and insulating coatings (lacquer, enamel, synthetic material, anodised aluminium, etc.) on conductive substrates (aluminium, copper, titanium, austenitic stainless steel).

In addition, all devices are capable of two different measurement methods:

Single mode: up to 70 readings per minute can be recorded and saved.

Continuous mode: up to 20 coating thickness values per second are recorded. This allows you, for example, to identify thinnest and thickest points and the saving of readings in a measurement series.

MiniTest 725

- internal probe

- saves up to 10,000 measurement values in 10 groups

- Prices and ordering options of MiniTest 725

MiniTest 735

- external, interchangeable probes connected via cable

- saves up to 10,000 measurement values in 10 groups

- Prices and ordering options of MiniTest 735

MiniTest 745

- interchangeable probes

- the probes can be connected internally as well as externally by cable and also without cable via Bluetooth

- saves up to 100,000 measurement values in 100 groups

- Prices and ordering options of MiniTest 745

Sensors

SIDSP – The best you can get in the field of measurement technology

SIDSP stands for “Sensor Integrated Digital Signal Processing”, meaning that a special microprocessor (DSP) collects, filters and processes measurement values in the sensor head. The benefits of this measurement technology for your application are as follows:

- Above average precision and repeatability

- Temperature compensation over the entire range of measurement

- Wear-resistant, polished probe poles made of carbide metal

- High immunity to electromagnetic (EMC) interference

- Measurement range up to a coating thickness of 35mm

- Each sensor individually factory-calibrated

- Automatic compensation of the conductive value for non-ferrous metals

With our decades of experience in the development of coating thickness gauges and specialised sensors, as well the application of the newest technologies, our SIDSP sensors make us a market leader in the field of non-destructive coating thickness measurement.

Applications

A diverse range of applications from a wide variety of sensors

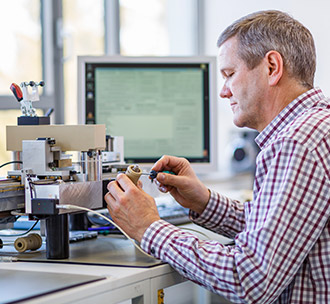

The compact design and the variety of sensor attachments means that the coating thickness gauges MiniTest 725 / 735 / 745 can be used for the most varied measurement tasks:

- Measurement of small parts, thin metal bars or in grooves: ease of use due to miniature sensors with the world’s smallest measuring head (diameter: 2.5mm).

- Automotive bodywork: the specialist sensors have reduced sensitivity to geometric factors and the thickness of bodywork panels.

- Aircraft construction: particularly challenging variety alloys based on aluminium or titanium are no problem for the MiniTest 700 since it automatically compensates for varying conductivity and can take readings on different non-ferrous substrates without the need for re-calibration.

- Measurements in holes and hard-to-reach places: attach one of the specialised tube sensors and it’s ready to go!

- Corrosion protection, e.g. in large steel structures (bridge construction and ship building): the devices in the MiniTest 700 series can record high volumes of readings in situ that can be analysed later.

- Environments prone to high levels of dust and moisture (construction sites, shipyards, etc.): heavy duty sensors are equipped with particularly robust measuring heads that can easily withstand different environmental conditions.

- Thicker coatings, e.g. fireproof coatings or special coatings in pipeline construction: the F 15 sensor allows you to measure up to 15mm coating thickness on steel.

- Measurement on highly abrasive surfaces with high roughness depth: specialised sensors also available.

The MiniTest 700 is therefore capable of overcoming almost any task in measuring coating thickness!

Operation and data transfer

Simple and comfortable operation – as equally important as precision readings!

When developing the MiniTest 700 series, we attached great importance not only to making sure that you can take precise measurements, but also to making the device extremely easy to use.

The device is operated using a menu on a graphic display. Instructions and help text in 20 languages guide you through the settings. Predefined calibration processes help you to calibrate according to international standards (ISO, SSPC, etc.). And a special measurement mode is available to optimise measurement on abrasive surfaces.

Data transfer is equally simple and convenient. You can transfer readings saved on the MiniTest 725/735/745 devices with complete ease to PCs, tablets or smartphones using a USB or Bluetooth connection. You can save up to 10,000 readings on the MiniTest 725 and 735 devices and up to 100,000 on the MiniTest 745.

This gives you the option to record readings on site that you can then analyse and archive at a later date.

The delivery of the device includes the data transfer software MSoft 7 basic. And for detailed analysis, the software can be upgraded to MSoft 7 professional.

Application

Non-destructive coating thickness measurement:

- Non-magnetic coatings like varnishes, enamels, chrome and zinc on ferromagnetic base materials (e.g. steel)

- Insulating coatings like varnishes and anodising aluminium on non-ferrous metals (e.g. aluminium, copper, die-cast zinc)

Measuring principles

- Magnetic induction (F-type sensors) according to DIN EN ESO 2808, method 7C

- Eddy current (N-type sensors) according to DIN EN ESO 2808, method 7D

Features

- Precision in coating thickness measurement of up to 15 mm / 0.59″

- USB and Bluetooth interfaces for data transfer to PC, mobile devices or printer

- Increased accuracy and reproducibility by sensor-integrated digital signal processing (SIDSP®)

- All sensors can be connected without cables to the MiniTest 745 device

- Universal probes with automatic substrate detection for quick measurements on steel and nonferrous metals

- Wear resistant probes with virtually unlimited life

- Storage for 10,000 readings (MiniTest 745: 100,000 readings)

- Optimal temperature compensation

- High precision characteristic curves with up to 50 data points in the factory calibration

- Integrated user guidance in 20 languages

Supply schedule

- Coating thickness gauge MiniTest 725, 735 or 745

- SIDSP sensor at choice

- Shoulder bag with belt clip

- Calibration set with calibration standards and zero reference plate(s)

- User guidance German/English/French/Spanish on CD

- Plastic carrying case

- 2 AA cells, type LR06

Coating thickness gauge MiniTest 725-735-745: calibration

Only a few calibration steps are necessary to adapt a coating thickness gauges perfectly to the measuring task thus assuring highest precision in coating thickness measurement.