Coating thickness measurement

Coating thickness gauge for quality control

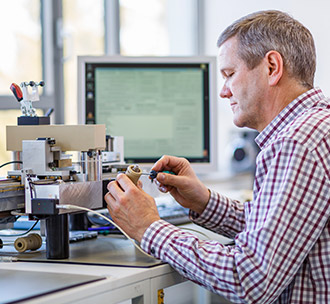

A coating thickness gauge provides quality control for many products and materials, such as steel and iron. Cars, ships, planes, industrial components and even mobile phones, as well as hundreds of other articles are all coated, generally using high-tech processes. On the one hand, such products require effective protection (e.g. against corrosion), with the aid of coating thickness measurement, to lengthen service life; on the other, they need to look good. Both aspects are equally important for customers, because both a product’s design and service life are vital factors in purchase decisions. Discover our high quality products under the “coating thickness gauge” category.

Our coating thickness gauges provide clarity − Reliable protection against corrosion and abrasion

Surface coatings can be paint, plastic or metallic such as zinc, chrome or nickel plating. To ensure a coating/measuring range can adequately protect the underlying material from corrosion or abrasion, a certain thickness is required, which varies according to the product being coated. This is where the measuring gauges for testing layer thickness come into play, using a surface measuring technique which reliably measures coating thickness.

Non-destructive coating thickness gauges

Coating thickness measurement is roughly divided into destructive and non-destructive measuring methods. Non-destructive methods are obviously preferred as these can be used for random sampling as well as for large-scale quality control. In the past, however, it was virtually impossible to measure coating thickness without damaging the protective coating. This is the reason why ElektroPhysik is proud to say, that we made it work. Due to many years of progression and growth and constant improvement, we are able to offer our customers gauges which combine traditional and established functionalities with modern technology and design.

Methods for coating thickness gauge

Several measuring methods and coating thickness gauges are now available that preserve the coatings. These include magneto-inductive methods for measuring non-magnetic coatings (paint, varnishes, etc.) on magnetic base materials, eddy-current methods for measuring non-magnetic metallic layers on non-ferritic metals, and ultrasonic measuring of non-metallic coatings on non-metallic base materials.

Coating thickness gauges for every need

We enable precise coating thickness measurement according to specific areas of application using equipment ranging from small, universally applicable coating thickness gauges with radio probe, Bluetooth and USB connectivity through to high-end gauges with a multitude of external sensors and graphic displays as well as a precision coating thickness gauge using ultrasonic pulse method and the MikroTest, a classic mechanical measuring device.

Do you have any questions about coating thickness measurement and/or our coating thickness gauges? We will be happy to answer them. Call us +49 (0) 221 75204-0 or write to us. By email to info(at)elektrophysik.com or via our contact form.

We are here to help you

finding the best solution for your individual measuring task as well as to answer all questions on coating thickness measurement in general and also when it comes to special topics, on calibration, quality requirements and many more. It is our pleasure to share our experience of more than 70 years in coatings industry with our customers.

Beatrix Badura-Yilmaz

Commercial director

Tel.: +49 221 75204-32

beatrix.badura-yilmaz@elektrophysik.com