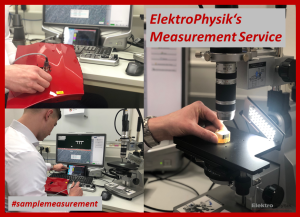

We process customer samples with exceptional precision!

You have a measuring task to solve and want to check whether ElektroPhysik offers a suitable measuring device? We offer our customers to send us sample parts free of charge.

Our application laboratory processes the sample parts according to the following procedure:

- Preparation of a cross-section for optical control of the coating thickness

- Measurements with the ElektroPhysik coating thickness gauges in order to select the most suitable gauge

- Preparation of a measurement report including precision and reproducibility

Most of our customers sample requests are for our ultrasonic coating thickness measurement gauge QuintSonic T. When we receive sample parts for the QuintSonic T, we can determine the correct software and parameter settings and exact sound velocities for each coating. So we can calibrate our instruments to each individual measurement task of our customers.

Most of our customers sample requests are for our ultrasonic coating thickness measurement gauge QuintSonic T. When we receive sample parts for the QuintSonic T, we can determine the correct software and parameter settings and exact sound velocities for each coating. So we can calibrate our instruments to each individual measurement task of our customers.

Thanks to a new lens from Keyence, ElektroPhysik is now able to resolve cross sections with 2000x magnification. This allows us to measure even the thinnest coatings with extreme accuracy. Due to the even more accurate resolution, the precision of the calculated sound velocity also increases, making our QuintSonic T even more precise.

Whether measuring on ferromagnetic substrates, non-ferrous metals, plastics, glass, CFRP & GRP or wood, ElektroPhysik offers you the best possible precision and ease of use.

Do you have problems solving a measurement task non-destructively, quickly and precisely? Feel free to send us sample parts and convince yourself of ElektroPhysik.

You can find our contact details here:https://www.elektrophysik.com/en/contact/

Recent Comments